Customer-Validated Fiber Optic Adhesive Performance Compared to EPO-TEK 353ND

2025-12-29Importance of Optical Adhesives in Fiber-Optic Connectors

Bonding optical fibers to fiber-optic connectors is a critical process to ensure precise fiber alignment, maximize optical transmission efficiency, and minimize signal loss. Selecting a suitable adhesive—typically a two-part heat-curing epoxy—prevents fiber displacement while mitigating the effects of mechanical stress and thermal variation on optical performance.

Fiber-to-Connector Bonding Process

Mixing

Mix resin and hardener at a 10:1 weight ratio.

Injection

Draw the mixed adhesive into a syringe and inject it into the fiber-optic connector.

Assembly

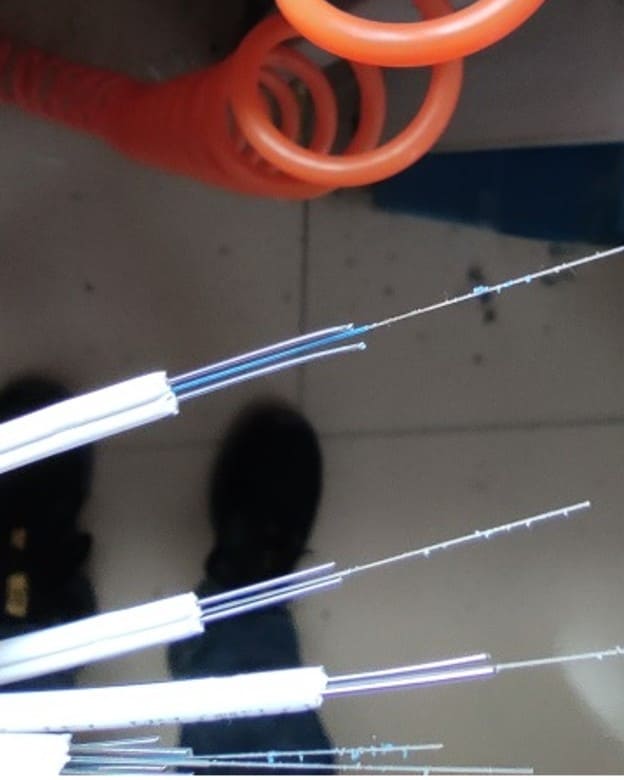

Strip the cable jacket and remove the fiber coating. After cleaning the fiber, insert it into the connector and apply adhesive to the fiber end face.

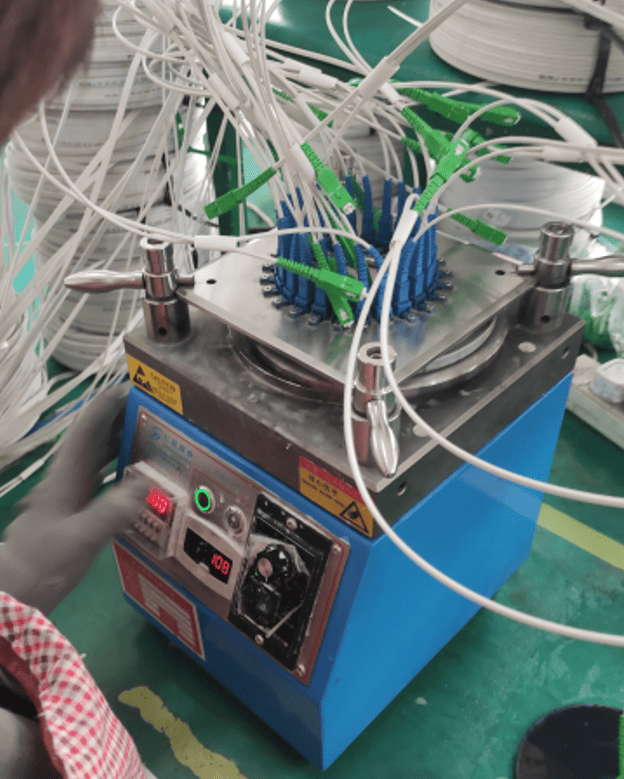

Curing

Place the assembled fiber set into an oven.145 °C for 15 minutes, or 80 °C for 40 minutes. After curing, trim the excess fiber tail.

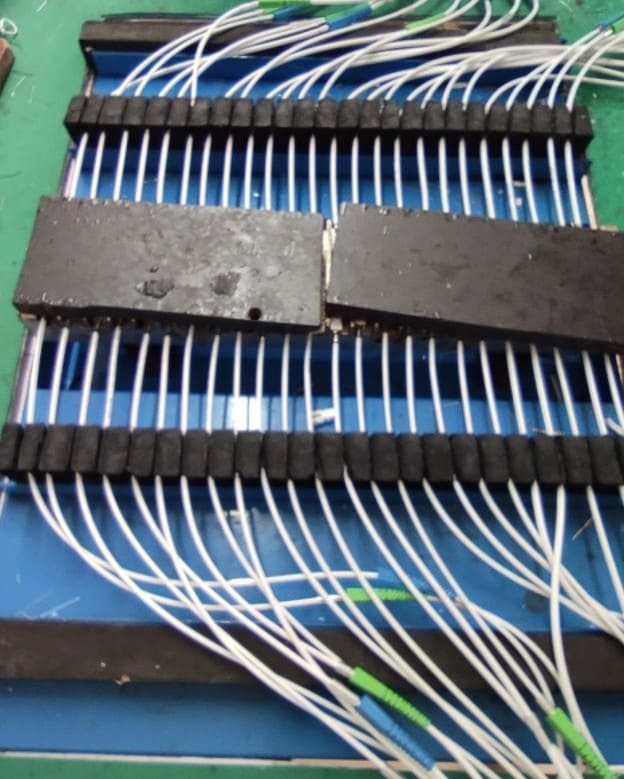

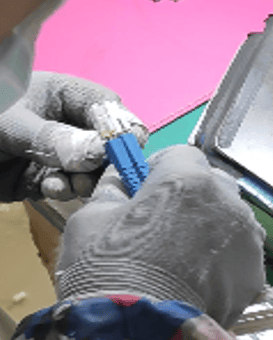

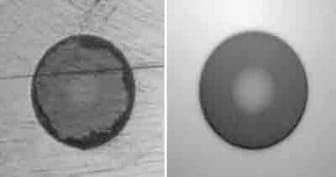

Ferrule Assembly & Polishing

Assemble connector components and polish the fiber using a polishing machine, followed by performance testing.

Finished Product Testing

Testing is conducted in reference to YD/T 1977.3-2015 (China Mobile standard): Optical Fiber – Part 1: Butterfly Optical Fiber.

Customer Feedback

The customer previously used EPO-TEK® 353ND, a widely adopted two-component heat-curing epoxy adhesive from the United States. Performance comparison with 3230 is shown below:

| Item | 3230 | EPO-TEK 353ND |

|---|---|---|

| 外觀 A | Clear, colorless liquid | Clear, colorless liquid |

| Viscosity A (mPa·s @25 °C) | 3888 | 3638 |

| Appearance (Part B) | Amber liquid | Amber liquid |

| Viscosity B (mPa·s @25 °C) | 156 | 323 |

| Mixing Ratio (by weight) | 10:1 | 10:1 |

| Mixed Viscosity (mPa·s @25 °C) | 3000 | 3545 |

| Pot Life (hrs @25 °C) | 6.5 | 6.5 |

| Recommended Cure (5 g sample) | 40 min @80°C 10 min @100°C 5 min @120°C |

30 min @80°C 10 min @100°C 5 min @120°C |

| Post-Cure Appearance | Dark red solid | Dark red solid |

| Tg (°C) | 100 | ≥90 |

| Hardness (Shore D) | 85 | 85 |

| Shear Strength (MPa, Al/Al) | 15.85 | 15.76 |

| Shear Strength after 250 °C / 48 hrs Aging (MPa) | 12.51 | 11.69 |

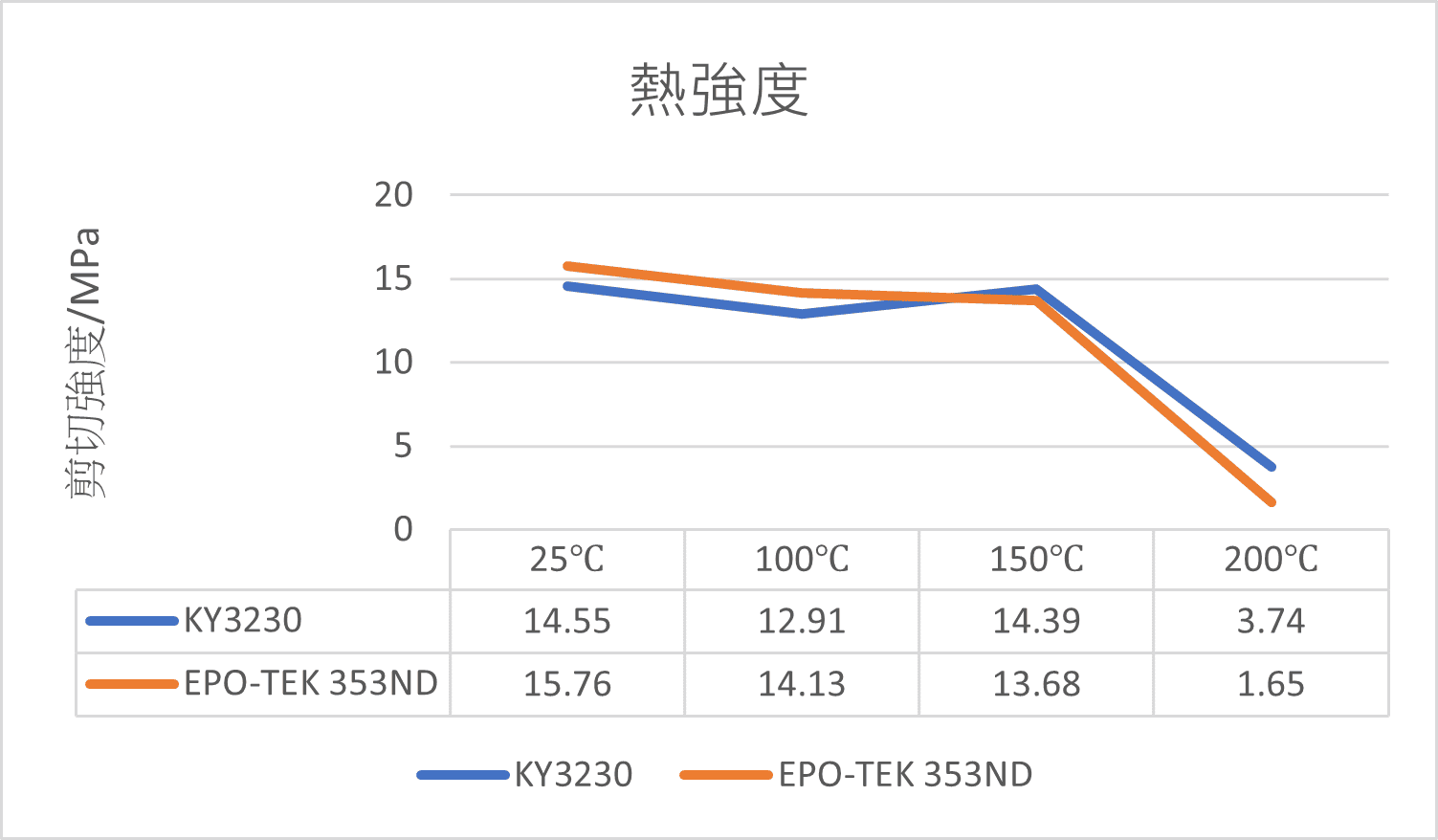

Thermal Aging Comparison

After 250 °C / 48 hours thermal aging, 3230 maintained slightly higher shear strength than 353ND after exposure to 150 °C and 200 °C, indicating superior thermal durability.

TDS Comparison

TDS data shows both materials exhibit highly similar key properties. Glass transition temperature (Tg) and coefficient of thermal expansion (CTE) are essentially equivalent.

| Model | Mixed Viscosity (cP) | Shelf Life | Cure Recommendation | Tg / °C | Working Time (hrs) | Post-Cure Service Temp (°C) | Mixing Ratio | CTE / K-1 |

|---|---|---|---|---|---|---|---|---|

| 3230 | 1500 ~ 4500 | 12 months @ RT | 120°C / 5 min | 100 | 3.5 ~ 4 | -55 ~ 250 | 10 : 01 | < Tg:60 × 10-6 > Tg:200 × 10-6 |

| 353ND | 3000 ~ 5000 | 12 months @ RT | 150°C / 1 H | ≥ 90 | ≤ 3 | < 350 | 10 : 01 | < Tg:54 × 10-6 > Tg:260 × 10-6 |

Incoming Material Testing – 3230

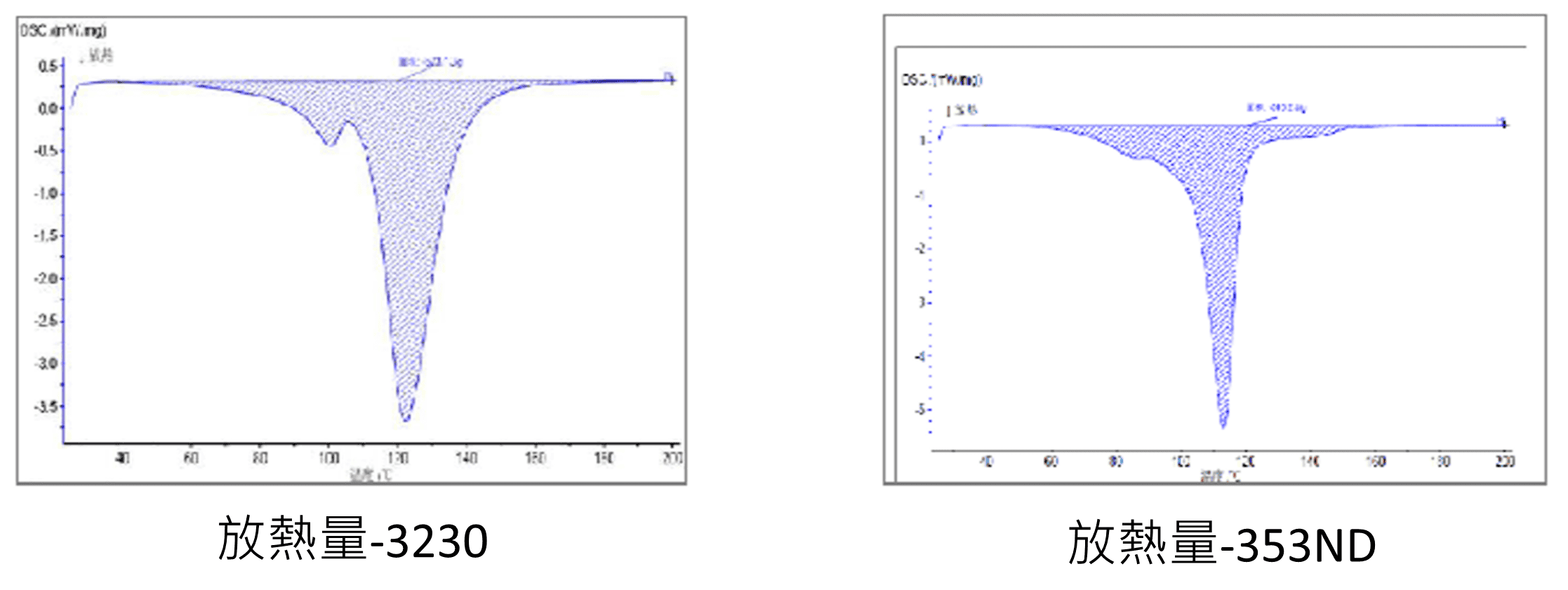

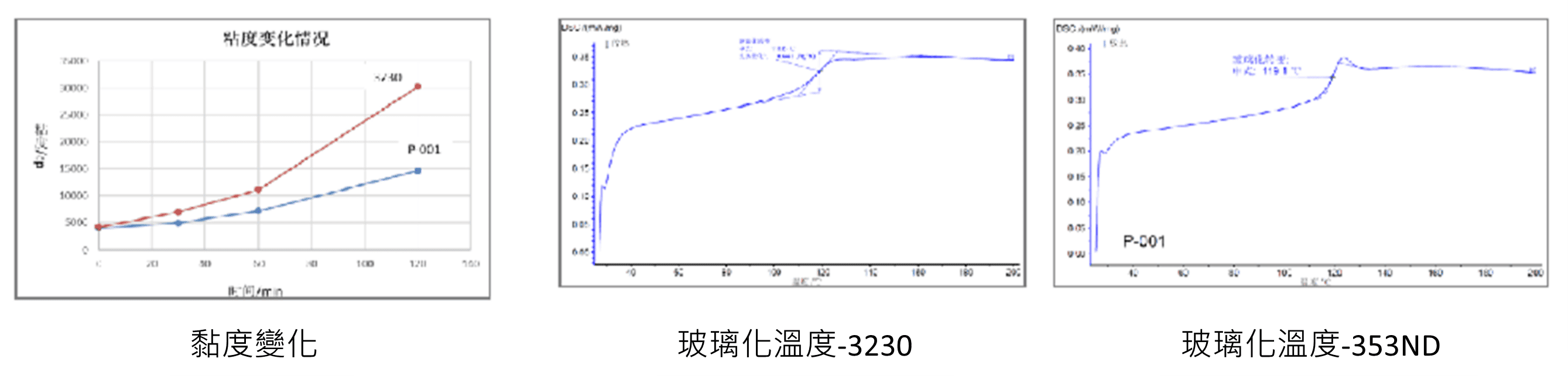

DSC Exothermic Analysis

The heat release per unit mass is nearly identical between the two adhesives, indicating highly similar resin formulations.

Viscosity & Glass Transition Temperature

Initial viscosities are comparable, with minimal change during the first 60 seconds. After 60 seconds, 3230 shows a faster viscosity increase than 353ND. Post-cure Tg values are similar, and both adhesives maintain excellent performance at elevated temperatures.

| Model | Batch No. | Mix Date | Viscosity (cP) | Cure Process | Cure Rate (%) | Tg (°C) |

|---|---|---|---|---|---|---|

| 3230 | 2020042401 | 2020.5.13 | 4200 | 150°C / 30 min | 100 | 118.6 |

| 353ND | 80000881001 | 2020.5.13 | 3987 | 150°C / 30 min | 100 | 119.1 |

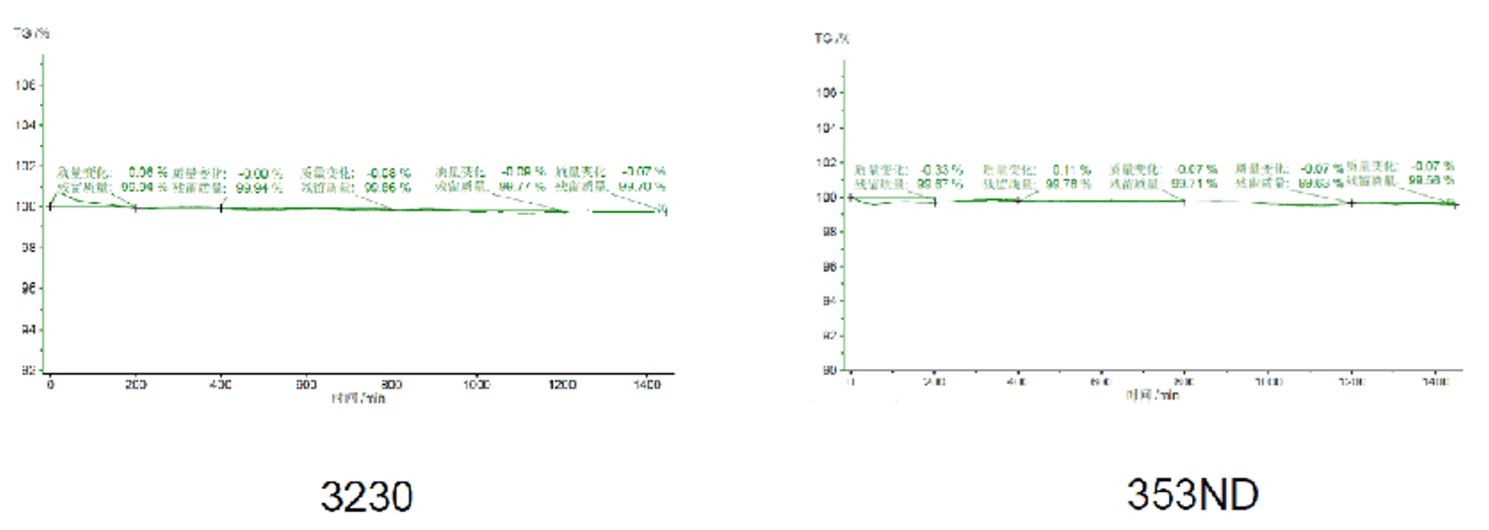

Volatility Test

No volatile components were detected after full cure for either adhesive.

Reliability Testing

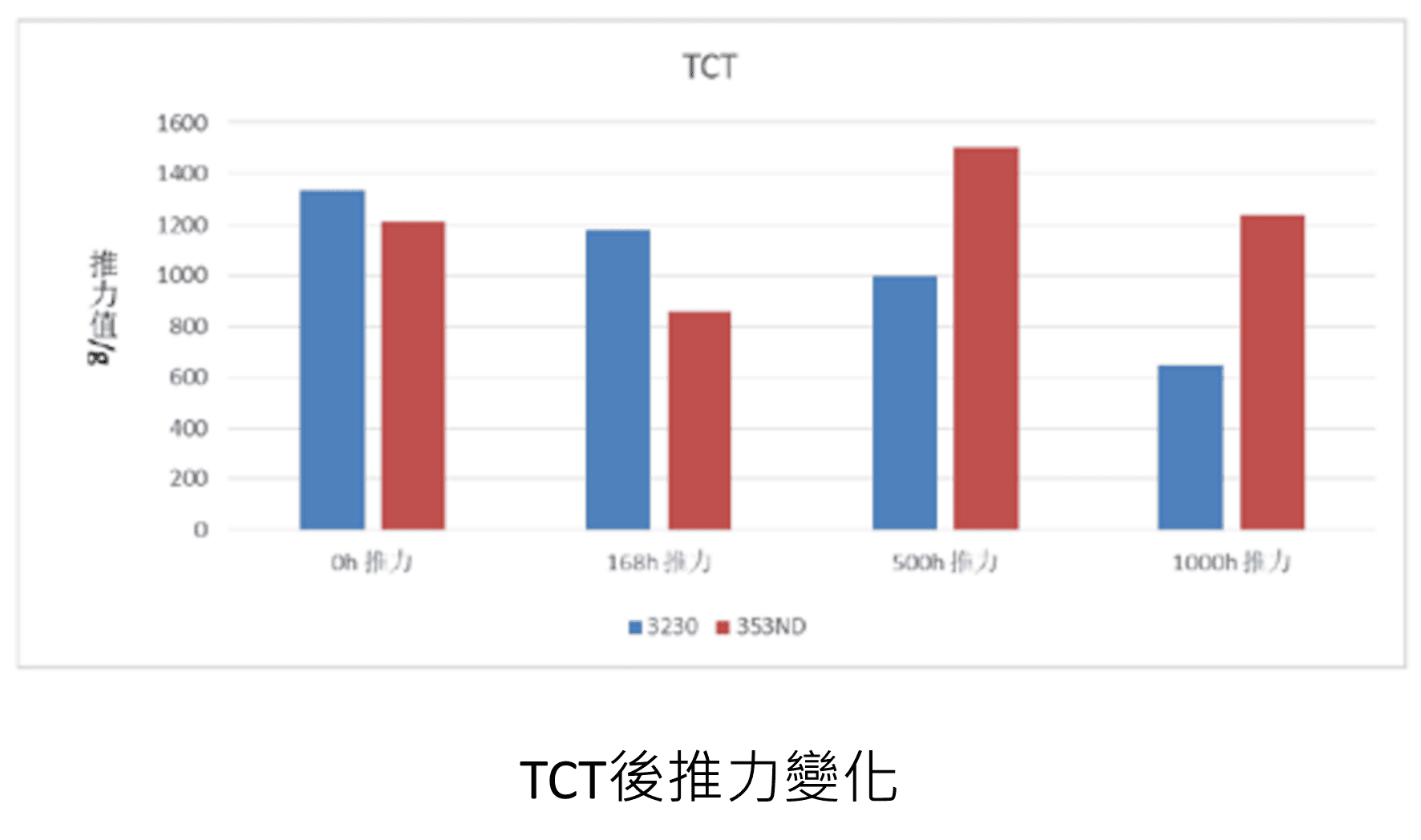

Temperature Cycling Test (TCT)

3230 exhibited a gradual decrease in pull force, outperforming 353ND in the early stage. After 500 hours, 353ND showed slightly higher pull force.

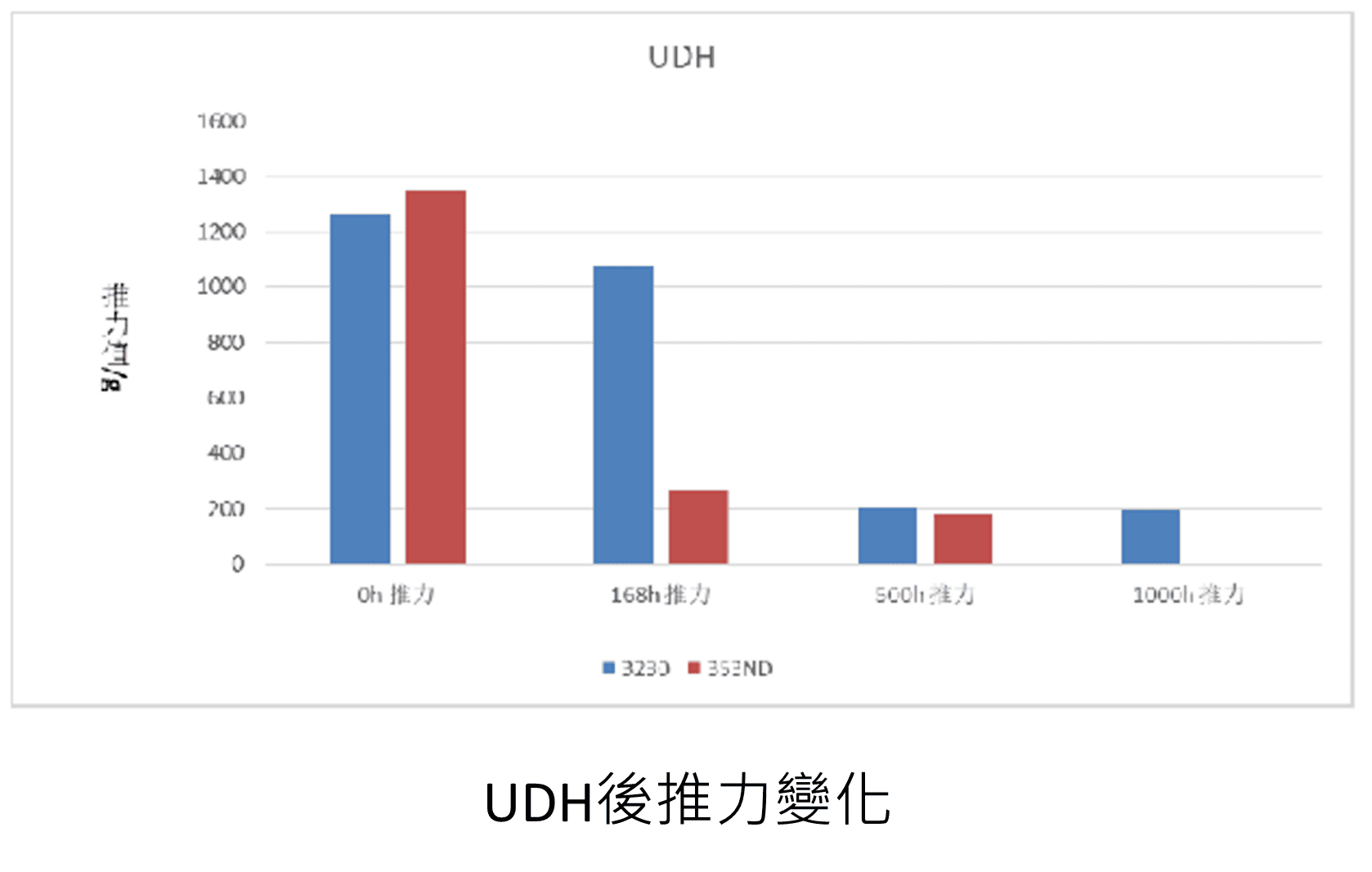

Unbiased Damp Heat(UDH) Test

3230 maintained higher pull force up to 168 hours before a sharp decline. In contrast, 353ND showed an early drop before 168 hours. Overall, 3230 demonstrated superior UDH performance.

Conclusion

The 40G optical product has successfully completed 500-hour reliability testing, showing stable performance equivalent to EPO-TEK® 353ND, with compliant volatility characteristics.